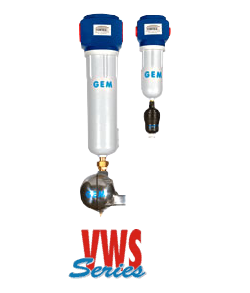

MOISTURE SEPERATOR - VWS SERIES

SALIENT FEATURES

- Compact Size

- Light Weight

- Zero Maintenance

- Float type Auto Drain Valve

- Easy to Operate

- Most effective separation of water and oil

- Non corrosive Alumnium body construction

- Sight glass for visually checking moisture collection

All air contains moisture in the form of water vapour. This water vapour begins to condense into condensate in the compressed air system when the air cools to saturation point. When this compressed air is used in the manufacturing plant, the moisture causes problems such as washing away of lubricants, increasing wear and tear, rust formation, corrosion etc. The easiest and permanent solution for moisture removal problem is the provision of a vortex separator..

Operation :

The moist air after entering the Vortex Separator hits the shell and then passes through the vortex generator, which generates the vortex motion of compressed air. The vortex generator is a fixed one and has a number of vanes. These vanes separate the moisture droplets by impingement separation method. Due to the density, the moisture droplets settle down into the dead zone below the arrestor. The moisture free air is let out through the inner shell of the separator. The arrestor will not allow the compressed air to carry the removed moisture. An automatic drain valve (float type) is fitted to the dead zone, which drains the moisture condensate. A sight glass is provided for visually checking the level of moisture collected in the dead zone.

GEM Vortex Separator is designed for 99% effective moisture separation with the least possible pressure drop.

TECHNICAL SPECIFICATIONS

| Model | Pipe Size | Flow Rates | Dimension | Weight | |||||

| cfm | m³/h | A | B | C | D | Kg | Lbs | ||

| VWS-010 | G 1/2" | 100 | 170 | 94 | 42 | 204 | 130 | 1.75 | 3.85 |

| VWS-012 | G 3/4" | 125 | 212 | 94 | 37 | 206 | 130 | 1.75 | 3.85 |

| VWS-015 | G 1" | 150 | 255 | 94 | 37 | 212 | 130 | 1.75 | 3.85 |

| VWS-025 | G 1 1/2" | 350 | 580 | 120 | 44 | 372 | 220 | 4.5 | 9.9 |

| VWS-040 | G 2" | 600 | 1000 | 173 | 63 | 468 | 340 | 7.5 | 16.5 |

| VWS-090 | G 2 1/2" | 1000 | 1700 | 173 | 60 | 471 | 340 | 9.5 | 20.9 |

| Line Pressure | bar g | 1 | 3 | 5 | 7 | 9 | 11 | 13 | 15 | 16 |

| psi g | 15 | 44 | 73 | 100 | 131 | 160 | 189 | 218 | 232 | |

| Correction factor | 0.5 | 0.71 | 0.87 | 1.0 | 1.12 | 1.22 | 1.32 | 1.41 | 1.56 | |

FOR SPECIFICATIONS / MORE DETAILS,

PLEASE CONTACT HEAD OFFICE

* Product Design and specifications are subject to change due to constant upgradation.